Jade, revered for its lustrous sheen and unparalleled durability, has long been a symbol of luxury and craftsmanship. Transforming raw jade stone into exquisite slabs suitable for high-end applications is a meticulous process that demands precision, expertise, and cutting-edge technology. From quarrying to refinement, each step plays a critical role in preserving the integrity and beauty of this precious material.

1. Sourcing and Extraction

The journey begins at jade quarries, where massive jade boulders are embedded within mountainous terrains or riverbeds. Extracting these raw stones requires specialized techniques, depending on the geological composition of the deposit. Miners employ diamond wire saws, hydraulic splitters, or controlled explosives to delicately separate jade-bearing rock from its natural bedrock without fracturing the stone.

Once liberated, these colossal jade blocks are transported to processing facilities for further refinement. Due to their density and hardness, handling raw jade demands meticulous planning to prevent surface damage or internal stress fractures.

2. Initial Cutting and Slabbing

At the processing facility, jade blocks undergo precision cutting to extract slabs of uniform thickness. High-powered diamond saws and multi-wire cutters slice through the stone with micron-level accuracy, ensuring minimal material waste. Water-cooled cutting mechanisms prevent overheating, which could compromise jade’s structural integrity.

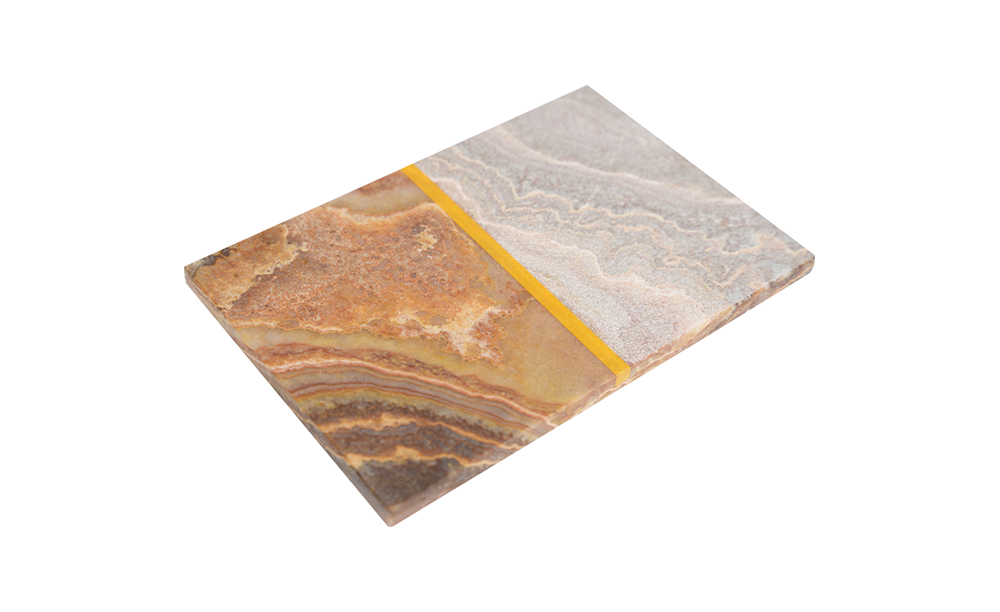

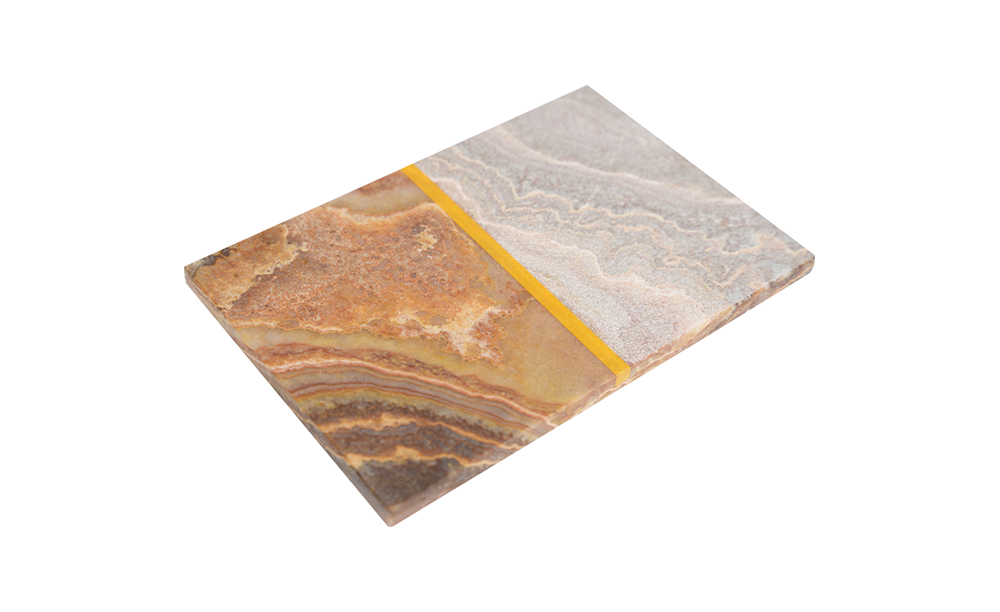

Each slab is examined for consistency in color, translucency, and internal veining—hallmarks that determine its aesthetic and market value. Any imperfections or fissures are identified through advanced scanning technology to ensure only the highest-quality slabs proceed to the next stage.

3. Fine-Tuning and Surface Enhancement

After slabbing, jade undergoes meticulous surface treatment to enhance its natural beauty. Depending on the intended application, techniques such as resin infusion, polishing, and honing may be applied. Polishing brings out jade’s signature luster, while honed finishes offer a more subtle, matte appeal.

To ensure a flawless finish, each slab is subjected to photometric testing and digital layout evaluations. This step guarantees precise color matching, seamless vein alignment, and optimal presentation for high-end installations.

4. Quality Assurance and Final Selection

Before the slabs are ready for market distribution, rigorous quality control measures are implemented. Each piece is scrutinized under controlled lighting conditions to confirm uniformity and structural integrity. Advanced imaging technologies, including spectrophotometers and stone scanners, assess translucency levels and detect microscopic inconsistencies.

Only the finest jade slabs make the cut—ensuring they meet the highest standards required for luxury interior designs, furniture, and architectural masterpieces. Once approved, slabs are meticulously packaged and prepared for shipment, destined to transform exclusive spaces with their timeless allure.

Conclusion

Extracting jade slabs from raw stone is an art as much as it is a science. It involves a harmonious blend of traditional craftsmanship and modern innovation, ensuring that each piece retains its inherent magnificence. Through this refined process, jade continues to be one of the most sought-after materials in the world of luxury architecture and design, captivating those who appreciate its rare and exquisite beauty.

English

English Français

Français عربى

عربى italiano

italiano